Drywall Screws

Drywall screws are used for fastening sheets of drywall to wall studs or ceiling joists. Compared to regular screws, drywall screws have deeper threads. This helps prevent the screws from being dislodged easily from the drywall.

Drywall screws are made of steel. In order to drill them into the drywall, a power screwdriver is needed. Sometimes plastic anchors are used together with drywall screws. They help balance the weight of a hung object evenly over the surface.

Types of Drywall Screws

The two common types of drywall screws are the S-type and the W-type drywall screws. S-type screws are good for attaching drywall onto metal. The threads of the S-type screws are fine and they have sharp points to make surface penetration easier.

On the other hand, the W-type screws are longer and thinner. This type of screw is designed for installing drywall onto the wood.

Drywall panels usually vary in thickness. W-type screws are usually driven into the wood to a depth of 0.63 inches while S-type screws are driven to a depth of 0.38 inches.

If there are multiple layers of drywall, then the screw should have a length enough to drive through at least 0.5 inches into the second layer.

Most installation guides and resources identify drywall screws as Type S and Type W. But most often, drywall screws are simply identified by the type of thread that they have. Drywall screws either have a coarse or a fine thread.

Drywall Screw Thread or Pitch

The pitch of a drywall screw is mostly classified as either coarse or fine. If the screw is threaded coarsely, then it holds tighter. Since there are fewer threads, it takes a very short time to screw it into place. Here is an example of a drywall screw with a coarse thread: SNUG Fasteners (SNG440) 145 Qty #8 x 2 Sheetrock Drywall Screws – Phillips Head with Coarse Thread

A drywall screw with a fine thread takes longer to insert but since they have sharper points, the screw is easier to insert. Here is an example of a drywall screw with a fine thread: Gray Phosphate Drywall Screws: #6 x 1-5/8” (5 lbs. approx. 1,134 screws) FINE Thread Drywall Screws (or sheetrock Screws)

If you are attaching drywall to softwood studs, then you should use drywall screws with coarse threads. A finely threaded drywall screw should be used for attaching drywall to light metal studs.

There are also specialty screws that are designed for specific purposes. This is used for installing drywall onto heavy metal studs. The drywall screws you need to use here is a self-drilling drywall screw. Self-drilling screws eliminate the need to drill holes in advance. For an example of a self-drilling drywall screw, consider this: U-Turn – 6 x 1-5/8 inch Self-Drilling Drywall Screws for Metal Studs (100 pack)

Coarse thread drywall screws are good at gripping into the wood because of their wide threads. This pulls the drywall against the studs. If used on metal, this type of screw will tend to chew through the metal and not gain proper traction. Since fine thread screws are self-threading, they can work with metal well.

Drywall Screw Length

If you are working with 1/2 inch drywall on wood studs, it is good to use a 1-1/4” or 1-5/8” drywall screw. You can purchase these screws in large tubs since you will need plenty of fasteners when you work with drywall installation. This type of screw is not expensive. Here is a good example: Senco 06A 125P DuraSpin Number 6 by 1-1/4” Drywall to Wood Collated Screw (1000 per box)

A shorter screw length would make driving it easier. However, a shorter screw length will also reduce holding strength.

For a ¼” drywall, use 1-1/4” drywall screws. For a 1/2” drywall, use 1-1/4” or 1-5/8” drywall screws. If the drywall is 5/8”, use 1-5/8” or 2” drywall screws.

Drywalls usually come in 1/2 inch thick panels. But thickness can also increase or decrease by a fraction of an inch. If you install drywall in your garage and walls adjacent to furnace rooms, you need slightly thicker panels to ensure that in case of fire, the spread of flames will be hindered. In this case, you will need a 5/8” or type-x drywall.

A ¼ “drywall is used for wall and ceiling facing. These walls are flexible and so it can be used to form curves. The majority of drywalls installed, however, is 1/2 inch thick.

Drywall Screw Gauge

When we speak of the drywall screw gauge, we refer to the diameter of the screw. Whole numbers are used to express gauge. The most common numbers are #6, 7, 8, and 10. Most of the time, you will use #6 and #8 drywall screws. As the screw becomes larger in diameter, the gauge number increases. So, a #6 drywall screw would have a smaller diameter than a #8 drywall screw.

For the actual size of the drywall screw gauge, a #6 gauge is 0.1380 “and the #8 gauge is 0.1640 “.

Gauge is usually expressed as the second number after the length. For example, a 1-5/8” long screw with a #6 gauge would be written 1-5/8-inch x 6. Here is an example: Grip-Rite 158CDWS1 1-5/8 inch 6 Coarse Threaded Drywall Screws with Bugle Head, 1 Pound

The standard material for drywall screws is low carbon steel. To protect the screw from corrosion, it is sometimes coated with gray or black phosphate. This is adequate to prevent the formation of rust caused by water-based paint before they dry.

Drywall Screws Features

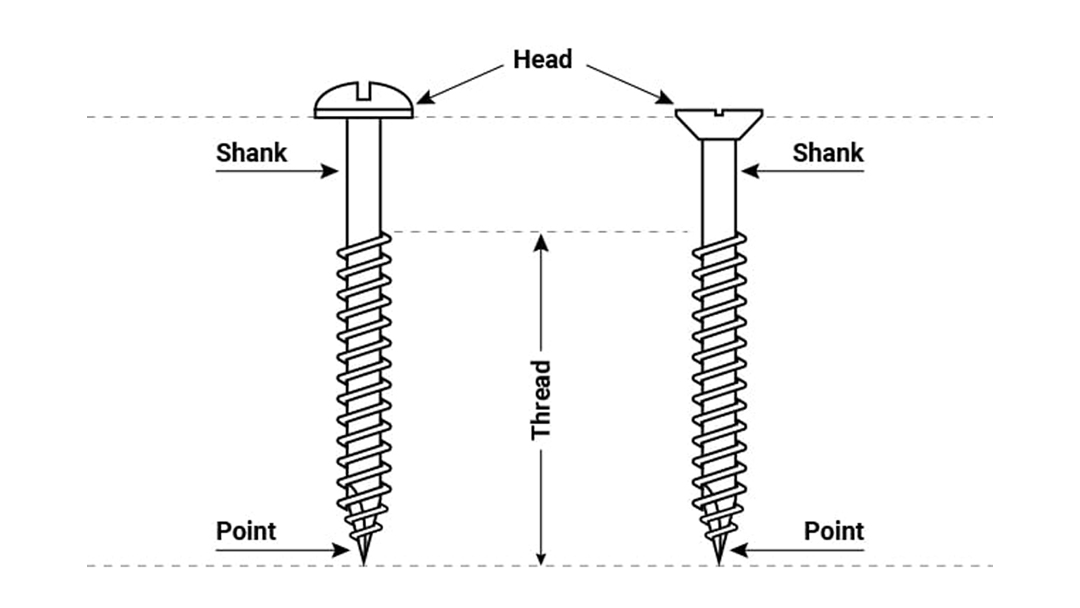

The head of a drywall screw is shaped like the bell end of a bugle. This is why it is called a bugle head. This shape helps the screw stay in place. It helps not to tear the outer paper layer of the drywall. With the bugle head, the drywall screw can easily embed itself into the drywall. This results in a recessed finish that can be filled with a filling substance then painted over to give a smooth finish.

There are drywall screws that have sharp points. With a sharp point, it would be easier to stab the screw onto the drywall paper and get it started.

Sometimes, if you buy a large box of drywall screws, the weight is measured instead of the number of screws. Take this as an example: Meite #6 Coarse Thread Drywall Screws by 1-1/4” Leg Length with Bugle Head, 5 Pounds Black #DSC114M (1 box)

A #2 Phillips head drill-driver bit is usually needed for most drywall screws. While other construction screws are already using Torx square or heads and not Phillips head, most drywall screws still use the Phillips head.

To resist corrosion, black drywall screws have a phosphate coating. Other types of drywall screws have a thin vinyl coating that makes them even more corrosion-resistant. Because these have slippery shanks, they are very easy to draw in. Here is an example of a black drywall screw with phosphate coating: (10000) #6 X 1/2” Drywall Screw Phillips Bugle-Head Coarse Thread Black Phosphate Bulk Box

Uses of Drywall Screws

Drywall screws are mainly used for fastening full or partial sheets of drywall to either wood or metal studs.

Drywall screws are also good for repairing nail pops. Nail pops are circular bumps you will see on your walls. These come from short, wide-head nails used to nail the drywall. Because of the nail-pop problem, drywall nails have been replaced by drywall screws as the standard method of attaching drywall to studs.

You can also use drywall screws for building projects. Since drywall screws are quite brittle, they can snap instead of bend. Its heads can easily break off and leave the shift section embedded in your wood. This is why drywall screws should not be sued for heavy or moderate building tasks. You should avoid using drywall screws for outdoor projects like fences and decks. You should only use drywall screws for light building projects.

Drywall screws can also be used for woodworking projects. When working with softwood, the coarse thread of drywall screws is perfect.

Drywall screws are also used by cabinet installers for installing and actually making cabinets. The drywall screw that is commonly used for cabinet installation has yellow zinc plating. This yellow zinc plating looks great with wood. It also gives an added corrosive resistance to the screw. Here is an example of a drywall screw with yellow zinc coating: (800) Phillips Bugle Head 10 x 4 Coarse Drywall Wood Screw – Yellow Zinc Bulk

Here are some bad uses of drywall screws

You should not use drywall screws outdoors especially in wet areas.

It is not good to use for your outdoor decks.

It is not safe to use drywall screws to install an electric box in the ceiling that will support a ceiling fan.

Don’t use drywall screws for stair framing whether inside or outside.

Never use drywall screws to fasten balusters to a handrail.

How to Drive Drywall Screws?

To drive drywall screws, you will need a dedicated drywall screw gun. This is a specialty tool for hanging drywall. It is compact, light, and has a lower torque than most cordless drills. The screwdriver should be accompanied by a drywall bit. With a drywall bit, the screw can sit at the correct depth. This will enable it to be filled and painted over.

The appropriate size of drywall screws should be selected. Make sure that the length of the screw is at least 10 mm more than the drywall thickness.

The location of the studs should be marked off. You need to lift the drywall panel to the right place. The screws should be more than 6.5 mm from the edge of the wall.

Adjust your screwdriver so that it is set to the proper depth. Then put the collated drywall screw on it.

Hold the drywall tightly while holding the screw gun to put the screws into place. Drive the screw into the drywall and the base material.

In order to properly drive a drywall screw, use the sharp point of the screw to pierce the outer paper. Place the drill-driver bit over the screw, turn on the drill and let the screw drive itself into the drywall and stud. To prevent the screw from camming out, exert more force when it is three-quarters of the way through.

You need to stop when you see that the head and the paper are even with each other. To let the screw sink just below the paper, apply another quarter or half-turn to the screw.

Screw spacing should be 12 inches apart. This means that when hanging a 48-inch sheet perpendicular to the stud, you will need around 5 screws.

You need to consult your local building code for you to determine fastening spacing for your drywall screws.

Difference Between Wood Screws and Drywall Screws

In order for your project to be successful, it is important to match the kind of screw to the kind of job at hand. You can know what material the screw is intended for by simply looking at the name of the screw. So, drywall screws are used for fastening sheets of drywall to wood or metal frames. Wood screws are used for fastening pieces of wood.

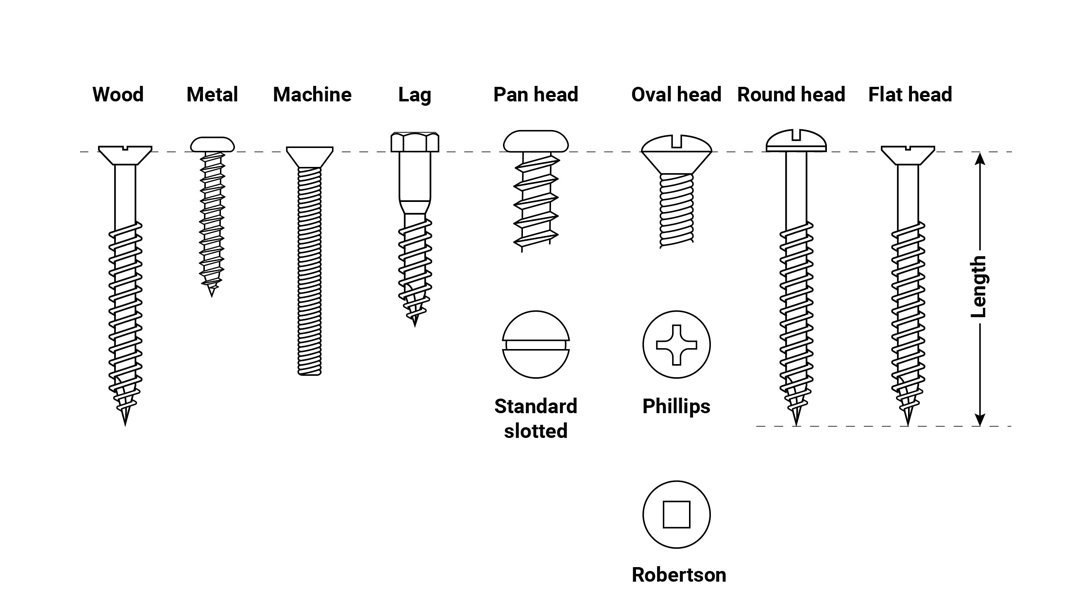

If you use stainless steel, flat head wood screws, then you will need either a slotted or a Phillips head screwdriver.

The material used for wood screws is zinc-plated steel, stainless steel, silicon, bronze, and brass. On the other hand, drywall screws are made of case-hardened steel. The colors of drywall screws are usually black because they are finished with black phosphate on the steel.

Wood screws are not threaded below the screwhead and it feels smooth. This smooth section of the wood screw slides by the top half of the wood so that the head of the screw and the threads can clamp together both pieces of wood. With drywall screws, there are threads almost all the way to the head.

A lot of preparatory work is needed when using wood screws. A pilot hole needs to be drilled beforehand for the threads. You also need to bore a wider hole for the length of the unthreaded shaft. Plus, a countersink hole for setting the head.

The numbering of wood screws is from 0 to 20. This indicates the diameter from 1/16” to 5/16”. Wood screw lengths are measure by fractions of inches from 1/2” to 4 inches. Drywall screws are numbered from 6 to 10. These numbers indicate threads per inch.

Wood screws come with different heads that correspond to the type of driver needed to install them. It also indicates the use to which the screw is being put. The different types of screw heads include slotted-head, Phillips head, flathead, oval head, and round head screws. Drywall screws have bugle heads. These heads are set a little below the surface of the drywall.

You need a pilot hole to get wood screws started. Drywall screws have hard, sharp teeth to make them self-starting. Self-tapping screws do not need a pilot hole. You can drive them directly into the drywall with a manual screwdriver or electric driver.

Difference Between Drywall Nails and Drywall Screws

When properly installed, drywall screws are more secure. However, drywall nails are much cheaper and easier to put in.

For Ceiling Installation

It is better to use drywall screws for ceiling installations. It is more secure than drywall nails. Drywall nails have to work against gravity. They will not be able to perform as well or as long as drywall screws.

For Wall Installation

Both drywall nails and drywall screws are effective for wall installations. Drywall nails are cheaper and easier to install.

Despite the cost of drywall screws, it will still come out cheaper to use them than drywall nails. The reason for this is that building codes call for up to double the number of nails as screws for hanging the same piece of drywall. And the cost of drywall screws is not double the cost of nails. So, you save with drywall screws in the long run.

Installing Drywall in Wet Locations

You should not use drywall screws outdoors or in damp locations because they easily rust.

There are those who coat their drywall with several layers of high-quality paint so that the drywall is protected from moisture. However, this is not always a good strategy.

If you want to install drywall in wet or moist areas, you need to use green board drywall. The Green board drywall is water-resistant. Its gypsum core has been treated with a water-repellent that is similar to silicone. Its outer paper is also moisture resistant.

To attach your green board drywall to wall studs, you need to use galvanized drywall screws. Your green board should be coated first with water-based urethane before finishing the green board.

With galvanized drywall screws, you can then install your green board drywall behind sinks, toilets, and on walls with ceramic tile backsplashes.

Using hot-dipped galvanized fasteners or stainless-steel screws will prevent it from rusting. You can use these to fasten your drywall panels to wall studs and ceiling joists. Using raw steel screws will rust in a matter of time. With rusted screws, your wall panels can fall off your walls or ceilings.